Detail

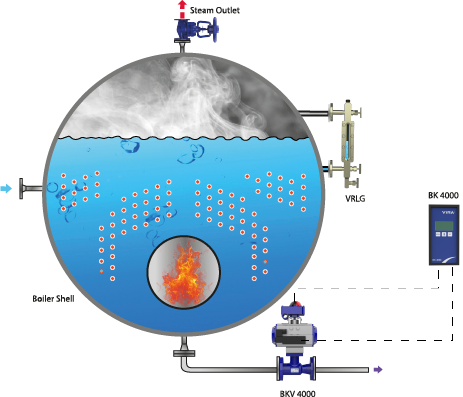

Vira Automatic Bottom Blowdown System (DB2)

Some impurities and salts (rust, oil and dirt that may come from the installation) precipitate to the bottom of the boiler to form a sludge layer. Thus, the heat transfer capability of the boiler is reduced and there is a danger of corrosion in the boiler. These foreign substances and salts should be periodically disposed out of the boiler to prevent the formation of the settling layer. For this, Automatic Bottom Blowdown Systems are used.

The method used to remove this sludge is using short, sharp blasts relatively large valve at the bottom of the boiler. The objective of this method is to allow the sludge time to redistribute itself so that more can be removed on the next blowdown.

For this reason, four-second blowdown is recommended in every eight hours rather than a single twelve-second blowdown in the first eight-hour shift, and does nothing for the rest of the day.

Blowdown water must either pass into a safe blowdown line going through under ground, or a metal blowdown vessel placed above ground. Vira recommends the use of a blowdown tank due to the flash steam contained in the blowdown water. Otherwise, the energy contained in the flash steam will be released to the atmosphere, causing energy inefficiency.

Vira Bottom Blowdown Valve

The Vira Bottom Blowdown Valve is a single-acting, spring return, pneumatic actuated automatically operated nodular cast iron or stainless steel valve. The command from the controller allows the valve to open with the air drive. Closing of the valve is also achieved by interrupting the air drive by the command from the controller and the return of the actuator spring. It's a bottom monoblock GG40 valve.

Vira Bottom Blowdown Controller

The Vira Bottom Blowdown Controller is used to transmit the command to the valve in order to blowdown at the desired time and desired duration. The Vira Bottom Blowdown Valve is not just a timer. Features that distinguish it from standard timers are as follows;

1- In case of any malfunction, you can get valve open and closed information from the controller in case the valve is over-blowdown or if it is closed or not blowdown.

2- In case more than one boiler uses a common blowdown line, the controllers of each boiler communicate with each other so that they are not operated at the same time.

| Controller | : | BK 4000 |

| Supply Voltage | : | 230 VAC |

| Functions | : | Automatic Blowdown, Valve Position Signal, Timer, Interval |

| Inputs | : | Limit Switch, Solenoid Valve, Blowdown Valve |

| Outputs | : | 1 Alarm Relay, 1 Valve Relay |

| Display | : | LCD |

| Button | : | 3 Pieces (Menü, Arrow, Set) |

| Max. Ambient Temp. | : | 55 °C |

| Enclosure | : | PA |

| Type | : | Panel |

| IP Class | : | IP 40 |

| Valve | : | BKV 4000 |

| Size | : | DN 25, 32, 40, 50 |

| Actuator | : | Pneumatic |

| Motor Type | : | On-Off, Spring to Close |

| Pressure Class | : | PN 40 |

| Body | : | WCB |

| Sealing | : | Metal to Metal |

| Supply | : | 220VAC, 24VDC (please ask) |

| Operat. Temp. | : | -10-+220 °C |

| Structure | : | Reduced Bore |