Detail

Accurate and automatic conductivity control in boiler water reduces the blowdown rate to a minimum and helps to save water treatment chemicals, water, and heat energy.

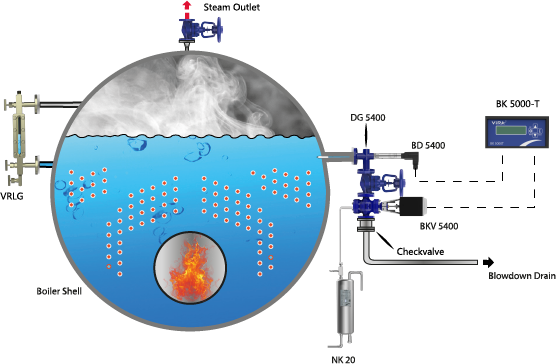

TDS Blowdown System

In steam boilers, TDS (Total Dissolved Solids) level is controlled more accurately and effectively with an automatic blowdown system. Automatic Blowdown Controller BK 5000-T measures the boiler water conductivity thanks to the Conductivity Sensor BD 5400.

The Blowdown Valve opens according to the high TDS signal from the BK 5000-T controller and closes when the TDS level reaches the set low value. BKV 5400 Blowdown Control Valve with electrohydraulic and spring return actuator is operated with the signal from the BK 5000-T Blowdown Controller.

The large display on the controller shows the TDS value in TDS ppm (number of parts per million) of the boiler water or the conductivity value in µS / cm (microsiemens / cm). At the same time, instant TDS and set TDS values are displayed.

Conductivity Controller BK 5000-T measures the electrical conductivity of the boiler water with the help of BD 5400 conductivity probe which does not have a temperature sensor within the body. So by using BS4 system, it is only possible to measure conductivity. so the conductivity values cannot be automatically compensated to the reference temperature of 25 ° C at changes in pressure and temperature. BS4 System is more suitable for the stable boiler systems. If the boiler system has variable temperature and pressure please use BS4-T system.

| Controller | : | BK 5000-T |

| Supply Voltage | : | 230 VAC |

| Functions | : | Conductivity Set, Cond. Hysteresis, High Cond. Alarm, Valve On-Off, Calibration |

| Inputs | : | Conductivity Probe Input, Ground, PT 100 |

| Outputs | : | 1 Valve On-Off Relay, 1 Alarm Relay, 4-20 mA Cond. Level Info, RS485 Modbus |

| Display | : | LCD |

| Button | : | 4 Pieces (Menü, 2 Arrow,Enter) |

| Max. Ambient Temp. | : | 55 °C |

| Enclosure | : | PA |

| Type | : | Panel |

| IP Class | : | IP 40 |

| Probe | : | BD 5400 |

| Connection and Size | : | Threaded - G 1/2''' BSPT (Optionel NPT) |

| Nominal Pressure | : | PN 40 |

| Length | : | 500 mm |

| Max. Operat. Press. | : | 32 Bar (g) |

| Max. Operat. Temp. | : | 239 °C |

| Max. Ambient Temp. | : | 75 °C |

| PT 100 Temperature Sensor Included | ||

| The length of the probe is fixed and cannot be adjusted after production. Therefore, the required length must be specified at the time of order. |

| Valve | : | BKV 5400 |

| Size | : | DN 20, 25, 40 |

| Actuator | : | Electric, Pneumatic (Optional) |

| Motor Type | : | On-Off, Spring to Close |

| Pressure Class | : | PN 40 |

| Body | : | WCB |

| Sealing | : | Metal to Metal |

| Supply | : | 220VAC, 24VDC (please ask) |

| Operat. Temp. | : | -10-+230 C |

| Type | : | DG 5400 |

| Nominal Pressure | : | PN 40 |

| Sizes | : | DN 20, DN 25, DN40 |

| Max. Operat. Temp. | : | 239 °C |

| Max. Operat. Press. | : | 32 Bar g |

| Body | : | Nodular Cast Iron, Carbon Steel |