Detail

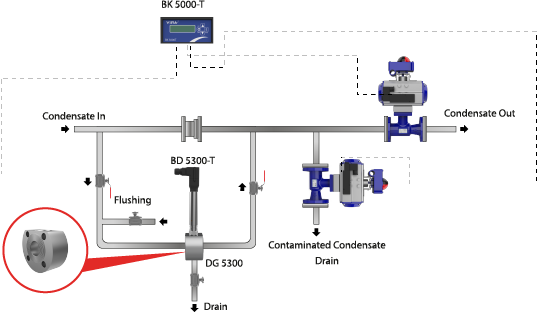

Recoverable clean condensate is a very valuable energy for steam producing enterprises. It is necessary to make sure that the condensate to be returned to the boiler room is clean. Perforation of a heat exchanger tube or plate means that the fluid to be heated mixes with the condensate. This causes the quality of the finished product to deteriorate and the returned condensate to be contaminated. Continuous control of condensate pollution means the protection of the boiler. Non-contaminated condensate means to maintain the quality of the product to be produced and to save energy. In case of any contamination, the controller sends a command to the valve to divert the condensate to the drain line and the dirty condensate is drained. In this way, the dirty condensate is prevented from returning to the condensate tank. When dirty condensate is detected, an acoustic or light alarm can be received and technical responsible can be informed.

BS3-T Condensate contamination control system monitors and displays the conductivity of the condensate. When the condensate conductivity level rises above the desired value, it directs the condensate water to drainage with a 3-way valve instead of automatically returning it to the boiler system. When the conductivity drops to the desired level, the condensate is allowed to return to the boiler system, thereby minimizing waste of heat and water, and also avoiding the possibility of contamination of the feed water.

Note: BS3-T Vira Condensate Contamination Control System performs contamination control with the conductivity measurement method. It cannot detect the presence of contaminants such as oils and sugars that do not affect the conductivity.

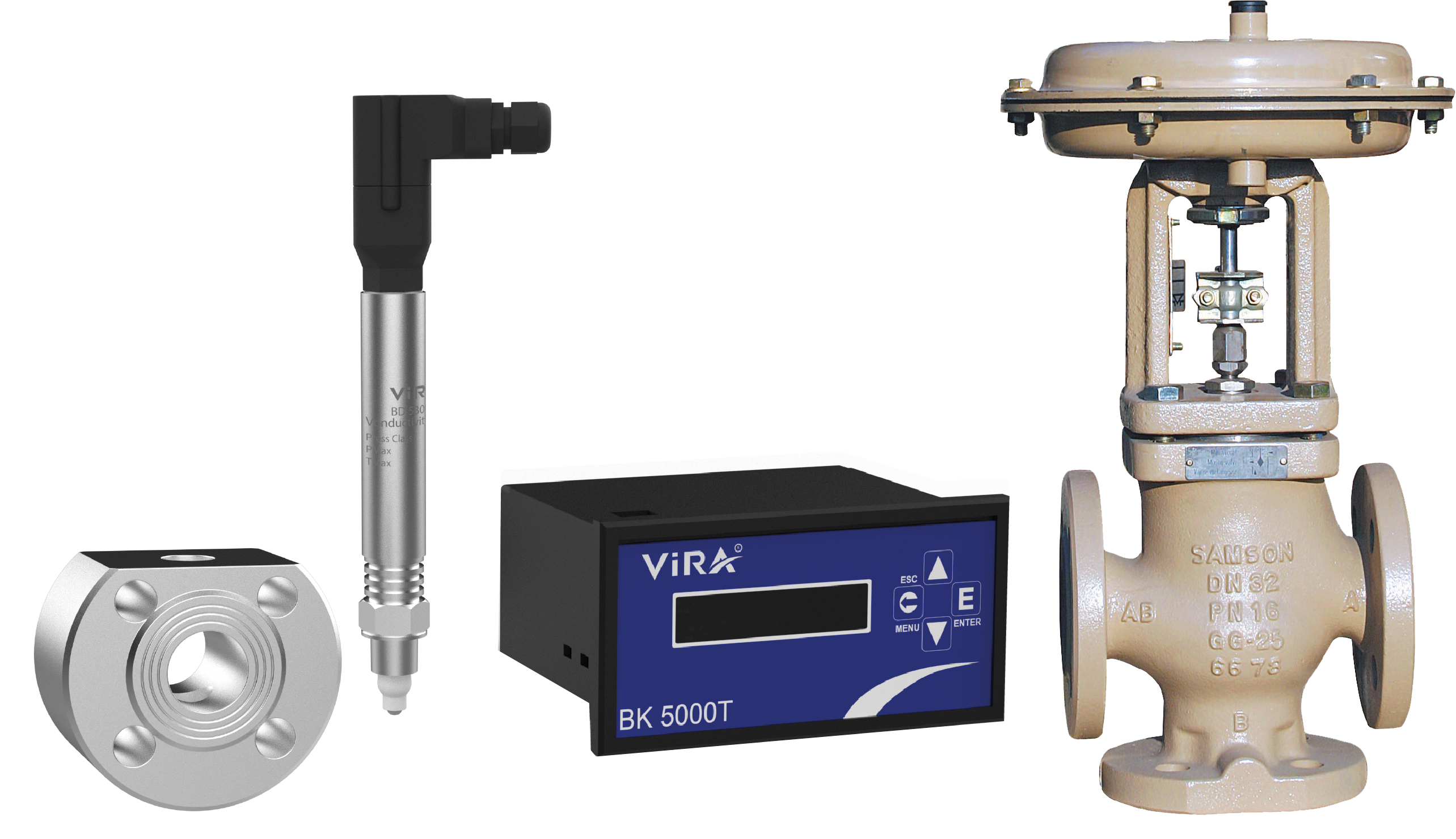

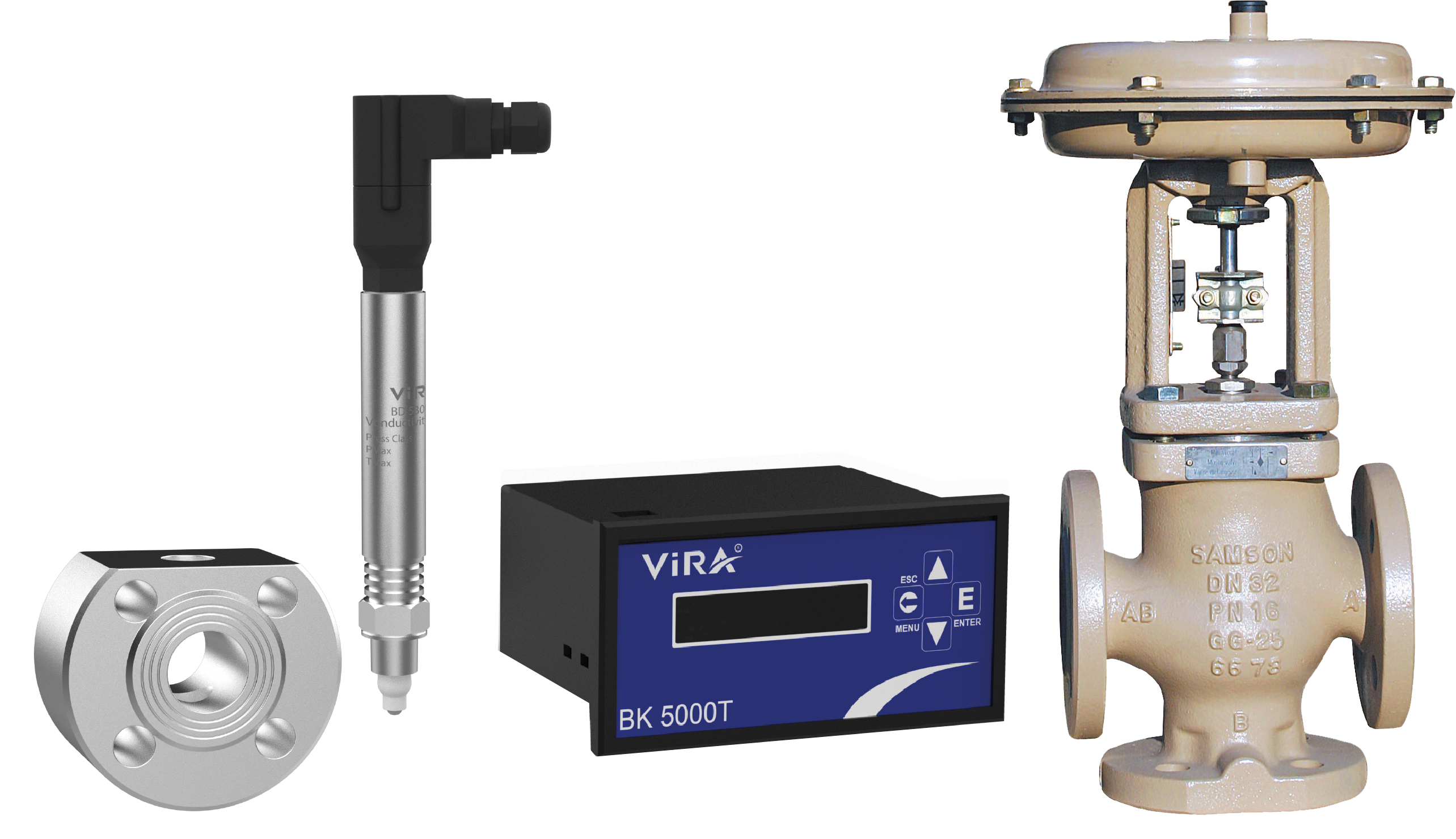

| Controller | : | BK 5000-T |

| Supply Voltage | : | Threaded - G 1/2'' BSPT (Optional NPT) |

| Functions | : | Conductivity Set, Cond. Hysteresis, High Cond. Alarm, Valve On-Off, Calibration |

| Inputs | : | Conductivity Probe Input, Ground, PT 100 |

| Outputs | : | 1 Valve On-Off Relay, 1 Alarm Relay, 4-20 mA Cond. Level Info, RS485 Modbus |

| Display | : | LCD |

| Button | : | 4 Pieces (Menü, 2 Arrow, Enter) |

| Max. Ambient Temp. | : | 55 °C |

| Enclosure | : | PA |

| Type | : | Panel |

| IP Class | : | IP 40 |

| Probe | : | BD 5300-T |

| Connection and Size | : | Threaded - G 1/2'' BSPT (Optional NPT) |

| Nominal Pressure | : | PN 40 |

| Length | : | 20 mm |

| Max. operat. Press. | : | 1 Valve On-Off Relay, 1 Alarm Relay, 4-20 mA Cond. Level Info, RS485 Modbus |

| Max. Operat. Temp. | : | 32 Bar g |

| Button | : | 239°C |

| Max. Ambient Temp. | : | 75 °C |

| PT 100 Temperature Sensor Included |

| Valve | : | SKV 3300-3 |

| Type | : | Diverting Valve |

| Pressure Class | : | PN 16, PN 25, PN 40 |

| Body Material | : | EN-JL 1040 - PN 16 EN-JL 1049 - PN 25 1.0619 - PN 40 |

| Operat. Temp. | : | -10 -+ 220 °C |

| Sealing | : | Metal to Metal |

| Actuator | : | Pneumatic |

| Type | : | DG 5300 |

| Body | : | Carbon steel, Stanliess Steel |

| Pressure Class | : | PN 40 |

| Process Connection | : | Threaded |

| Probe Connection | : | Threaded |

.png)